Below is some edited correspondence that may be of general interest. Some company names mentioned in the incoming have been removed as a courtesy to any manufacturers who I don’t think ought to be subjected to indefensible hearsay.

—– Original Message —–

From: Jason

To: Ted Clements

Ted

We are in New Caledonia, which is very French. Next we will spend a week sailing to Australia in early December.

While in New Zealand with the boat I observed at least six –bleep-*well known French Cats* in boatyards having major work done to them. One of the boatyard owners said, “I love hauling these boats out, most of them need major cross member and fiberglass work (inside and out) to eliminate their independently moving hulls; damage from which occurs after a few thousand miles of sailing.” The yards apparently make big bucks correcting these design and/or manufacturing defects.

Earlier in the year a 40+ foot ‘bleep’ mono gybed in high winds. The mainsail preventer was rigged wrong so the boom bent mid-way and the mainsail slammed into the lee stay, which instantly broke the spreader and battens. The sails were quickly dropped, the wiggly mast stayed basically vertical, and the owners motored about 1,000 miles to the next port. When the boat reached civilization the owner told the rigger to buy the best boom on the market. He now owes a Seldén boom.

Catamaran rigs are getting a very bad rap this season in the South Pacific. Eight have lost their masts, six of them cats built in South Africa, two built in France. The mono owners are loving it. This is a list you want to stay off of at all costs!

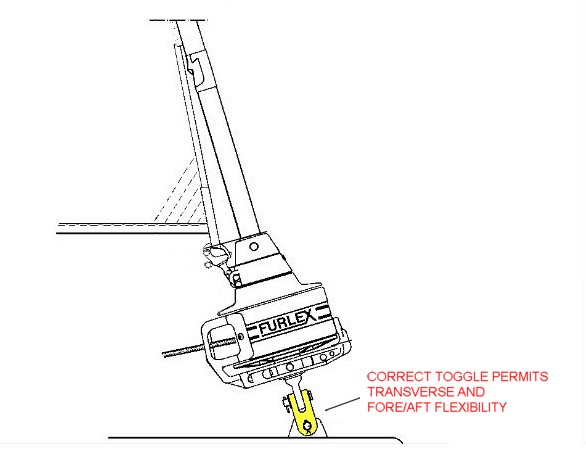

All of one manufacturer’s cats appear to have suffered from the same root cause…the toggle under the furling drum gives way. No forestay….no standing rig. The one at the dock near where I’m anchored has a bent toggle. The tang welded to the cross beam is very small, not very thick, and it is PERPENDICULAR to the crossbeam. Their toggle fits tightly down both sides of the plate and is pinned to it. So, to my eye the toggle cannot move starb’d-to-port without bending; which in the case of the yacht at the dock, has done.

It has a Profurl furler, the toggle looks rather thin, compared to the Seldén one on our boat. The owner announced that he will replace the toggle when he gets to Australia, which is 820 nm away. I would never play that hand, would you? I would think that the boat manufacturer and Profurl would try to get out in front of this type of significant equipment failure.

On my 44 Antares catamaran there is a heavy-duty gull-striker plate (my term which might not be correct) at the center of the cross beam and below the furler. This plate runs parallel to the crossbeam and is double thickness where the forestay attaches to the plate. The Seldén attachment hardware allows our forestay and furler to move right to left and forward to back.

One cat’s sidestay swage parted in 12 knot winds. The two man crew was able to save the spar and motor to Australia.

I heard that another’s “wire broke,” whatever that means. In fact, given the distorted grape vine in the cruising community, it’s awfully hard to get the facts but I have firsthand details concerning the most of these issues.

I’m guessing that most cat owners tend to push their cats in strong winds. This combined with the fact that most of us are probably heavily burdened, might be part of the root cause. I, like most of the men, point the fingere at my wife who just smiles and says, “More space for more things.” To keep sailing, the men don’t get overly aggressive when it comes to getting the junk off their boats. And, the truth is I have a ton of extra parts, materials, and fuel cans on YOLO.

So, the million dollar question for you is…have any of the Antares catamarans had any rigging failures?

Mine is approaching 10 years old and I give the rig a detailed inspection at least twice per year. Each inspection takes over 2 hours. I completely rebuilt the furler last year and did the same for the hundreds of pieces in the mainsail cars the year before. I’ve replaced several worn sheaves on the boom.

Is there a recommend period of time or distance traveled standard for having a major refit/overhaul of Seldén rigs? If so, what are the details?

– Jason, S/V YOLO –

From: “Ted Clements”

To: “Jason “

Jason,

No Antares 44 catamarans have lost their rigs (or even experienced any close calls that I know of). Seldén engineered the spars and standing rigging according to the initial righting moment for the vessel, and though it has become operationally generally heavier (inevitable it seems), the loads fall within their calculated safety factor (evidently).

I don’t know that boats being heavier due to cruising gear is a valid rationalization for rig failure since relying on the maximum righting moment value to provide an engineering ‘safety valve’ really means that the rig will not be blamed for an unhappy day, (the forefront issue in that case being a capsize). Presumably a design responsibly intended for cruising will have a significant safety margin built in to its engineering considerations.

Mast engineers are wise to be chicken in this regard and indeed they did demand some heavy duty hardware and double spreader/jumper rig in our case (which appeared to be a bit of possible overkill at the time).

I have heard the question, ‘In this circumstance, shouldn’t the rig go first?’ As the dangers inherent in an unpredictable rig failure and the impossibility of pre-determining just the right circumstances when that should occur, the argument is academic and we are left with presuming the mast should continue to ‘stand’ and point at the seafloor in the eventuality of capsize. This is the only supportable engineering position to adopt and some considerable allowance for the growth in vessel weight needs to be built in to the calculated safety factor. Mast engineers are wise to be chicken in this regard and indeed they did demand some heavy duty hardware and double spreader/jumper rig in our case (which appeared to be a bit of possible overkill at the time).

Your list of lost spars this season seems to reflect some poor fit-out and possibly maintenance rather than engineering calculation failures; the lack of transverse flexibility in the furling hardware attachment being one example. It sounds as if there is no toggle arrangement as illustrated below, perhaps the toggle used was a wrong type?

The transverse tang above has to be fabricated to approximate the fore/aft angle of the forestay. A toggle is still required for flex with either configuration.

This is possibly a case of too many cooks involved in the engineering/purchasing/manufacturing/commissioning stew; the inadequacy of the furling toggle arrangement could well be self-evident to everyone involved but which among them is responsible for identifying and fixing it before the owner sails away?

Stepping a large mast always seems to have an element of urgency about it (hourly crane charges?) and expedients may be resorted to, but it is imperative that confirming the correct hardware and its connections is not forgotten. Mistakes can always happen.

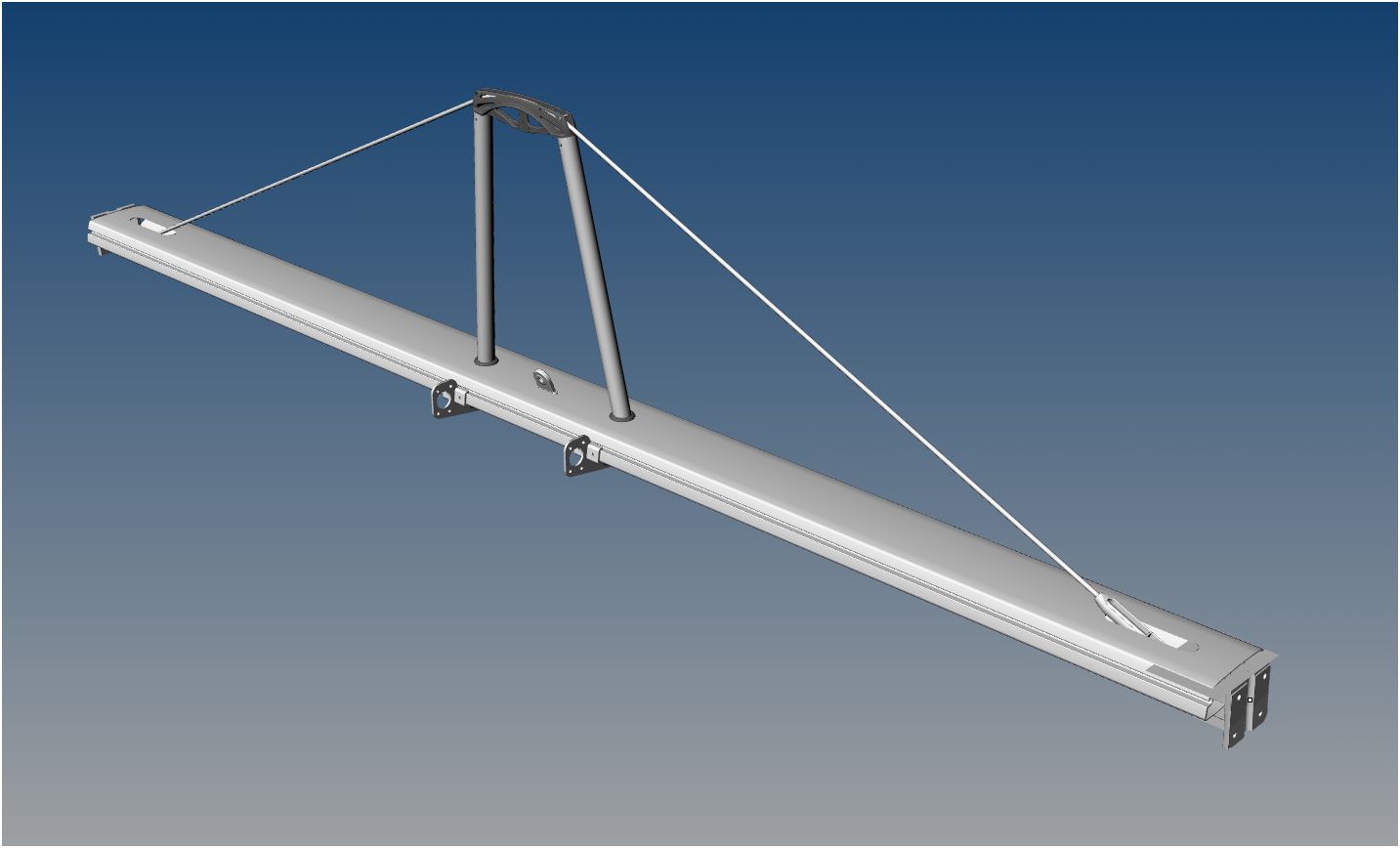

Making a point of trying to single source the spar and rig, (even if it isn’t necessarily the most economical thing to do), will ensure that all components are compatible and consistent at least. This also simplifies the identification and rectification of problems needing solutions (also helps with blame assignment). When your boat was built, the crossbeams were built by Klaco Spars to our requirements. Later production used Sparcraft crossbeams using a configuration shared with some similarly sized French cats.

Though both of these arrangements have been totally satisfactory, Seldén crossbeams are now available so we are currently consolidating supply with them, consistent with the policy of ensuring general compatibility. This makes all the spar, standing rigging and furling gear equipment the product of a single engineering desk.

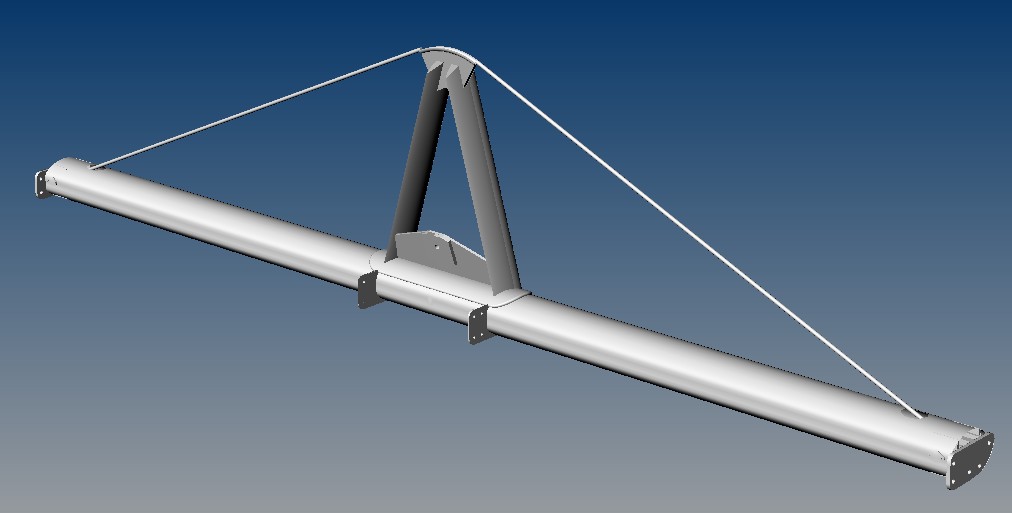

Your early production crossbeam is perhaps a little overbuilt in fact but we were disinclined to take any chances.

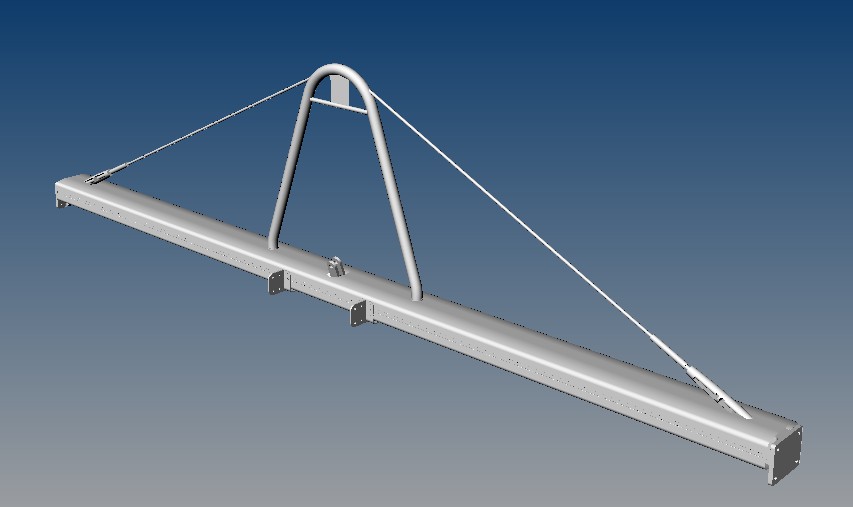

The doubler plate on the top surface of your crossbeam and the inclined gusset plate to which the forestay is attached are part of the ‘A’ frame construction that carries the crossbeam stay load down to the forestay tang.

Regardless of the supply for spars and rigging etc., whether a mast stands or falls depends most often on the integrity of the fit-out.

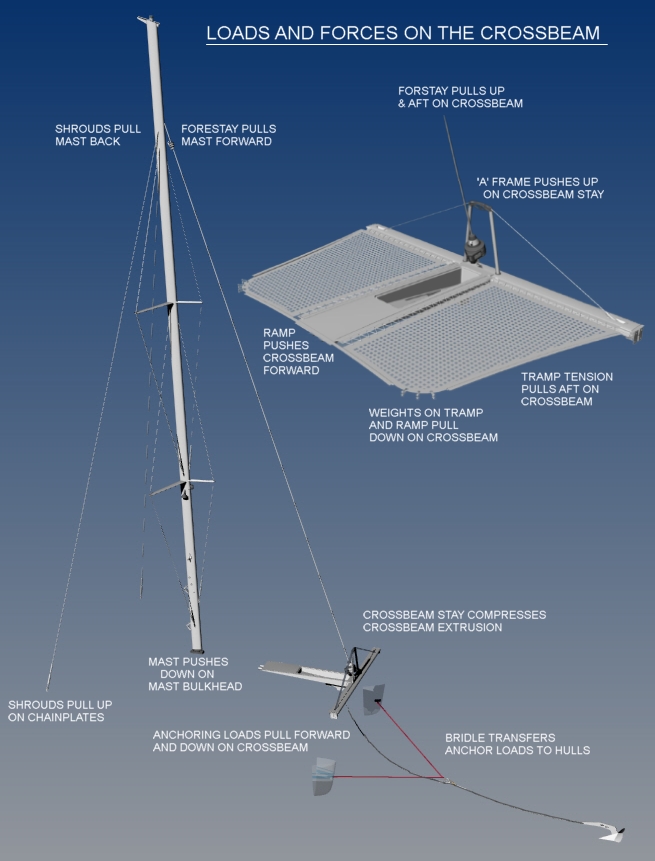

All the Antares catamaran crossbeams use the same engineering; the crossbeam stay presses down through the ‘A’ frame to resist the forstay pulling up. The forestay thereby imposes no vertical bend loading within the crossbeam itself and the extrusion is only lightly loaded to position and stabilize things. The forestay loading puts the crossbeam stay wire in proportionate tension which then puts the beam in compression over its whole length.

To illustrate the forces at work more directly, the crossbeam example below simply attaches the forestay directly to a crossbeam stay wire (bridle) without an ‘A’ frame. That places the furler and sail tack rather higher than we may want them in a larger vessel and precludes the possibility of supporting the crossbeam itself with the forestay.

The quite significant trampoline tension load wants to bend the crossbeam aft as does the forestay to some degree (the crossbeam stay and ‘A’ frame are approximately vertical and therefore out of plane with the forestay); those loads are resisted by the centre trampoline ramp which is in compression.

The more obvious trampoline weight loading generates a downward pull on the crossbeam that is resisted by the forestay pulling up; a load eventually absorbed by the mast in compression and the shrouds in tension.

The ground tackle may also exert a heavy downward pull of the crossbeam, the vertical loads being eventually absorbed indirectly by the forestay via the anchor rollers and trampoline ramp attachment. The use of an anchor bridle arrangement relieves the assembly and the rigging of anchoring loads.

Though the crossbeam extrusion has some inherent bend strength, in the absence of the forestay support is not designed to resist the possible extremes of loading that anchoring may produce. In this circumstance any vertical loads placed on the anchor rode either by windlass or wave bounce in an attempt to break free a fouled anchor may put the crossbeam in excessive bend loading. When the vessel is canalling with the mast un-stepped, this has to be kept in mind. (Nobody has bent one of ours yet.)

Regardless of the manufacturer, the crossbeams all work with the same physics and geometry. The mechanics are becoming more refined I would say as the sailing catamaran fleet and the body of experience grows.

These issues may just be some things to contemplate when bored but it helps to appreciate the nature of the loading when doing your inspections.

I think regular visual inspection and periodic disassembly is the right thing to do. I have heard of racing wire being replaced after a very short use, and a recommendation to replace cruising wire after three seasons but I think that kind of approach is wasteful and presumes you are delighted by rampant consumption. Every installation will be subject to different conditions and maintenance etc. so the decisions should be based on the state of the equipment itself rather than some arbitrary calendar number. The swages and terminations in the wire are the most vulnerable areas and may have some hidden deterioration so with this in mind, after several seasons and in anticipation of arduous times ahead, something more in depth than a visual inspection may be in order, like an x-ray or penetration dye operation perhaps. I have seen this recommended as a five year exercise but once again I think it depends on what has transpired in the interval and how excitable you are. In the presence of reasonable vigilance, things still go wrong occasionally, but in my experience the thing that fails is not one of the “somethings” that has been reasonably anticipated.

This is the link to Selden’s latest maintenance suggestions, it gets added to periodically so you may want to get the latest stuff; http://www.seldenmast.com/frameset.cfm?id=6740&randnum=661167892

Regards,

Ted